CROST: on the track of affordable tramways

Talk by Lewis Lesley

UCL 4th March 2009

Track laying in Manchester, 1990

Reducing costs

Infrastructure

Not relocating utility plant would not only save considerable disruption (3.4km of utility relocation in Central Manchester in 1991 took over a year), but also costs (utility diversion for the Leeds Supertramway would have been £100m out of a total of £400m). The cost, time and disruption of diverting utilities in Central London would be very high.

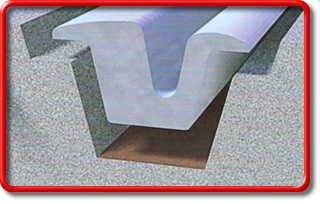

The low impact street tramway system proposed for CROST does not disturb under street utilities and maintains access to them, as the foundation trough is only 180mm deep and 380mm wide. It has been in maintenance free operation on the Sheffield Supertramway since March 1996, where it replaced the original track that had failed after just one year.

The LR55 track in Sheffield; 14 years maintenance free

The LR55 track in 3-d

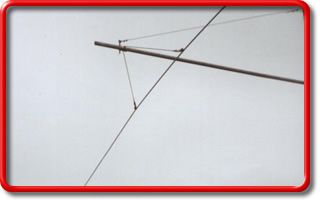

TPL OHL compared to WCML at Carnforth

Electric trams need a power supply. Traditionally this has been via an overhead line, supported from lamp posts, traction poles, or directly from adjacent buildings, without poles. In the UK another source of complaint is that OHL has got heavier and uglier. This commentator likens the Tramlink OHL, to the West Coast Main Line plonked down in the streets of Croydon. There are elegant solutions to OHL. Indeed the tram OHL through the Vienna World Heritage Site, is supported directly off the Opera House, without a mast in sight. Not only are such designs less intrusive than say the Regent Street decorations but they also are very economical and quick to install. This still leaves the need for substations, needed every 2km or so. These have reduced in size and can now be incorporated in existing substations, or included in the basement of an adjoining building.

Tramcars

Trams are not proprietary products and there are many manufacturers who can supply suitable trams to carry the expected patronage safely and comfortably. As the NAO Report noted the main tramcar builders have costs that are much higher than other public transport vehicles, like buses. Many trams are effectively reduced versions of main line trains, and on a per passenger basis, are heavy.

Table 6 Comparison of vehicle weight per passenger

| Type of Vehicle | Unladen kg | No. of passengers | Kg per passenger |

| Bus | |||

|---|---|---|---|

| Single deck rigid | 9000 | 53 | 170 |

| Double deck | 12000 | 84 | 143 |

| Articulated | 18000 | 140 | 129 |

| Trolleybus | 13000 | 100 | 130 |

| Train | |||

| Metro car (electric) | 32500 | 150 | 216 |

| Suburban (diesel) | 35400 | 120 | 296 |

| Tram | |||

| Tatra T5C5 | 19500 | 100 | 195 |

| Manchester Metrolink | 46000 | 200 | 230 |

| Sheffield Supertram | 54000 | 220 | 245 |

| City Class | 22000 | 200 | 110 |

After Lesley 1994

More weight means higher power consumption. The table below shows the comparative power consumption of some different trams in the UK

Table 7 Power consumption of different UK tramcars

| Tram type | Weight (tonnes) | Power use (kWh/km) |

| Blackpool Centenary | 18 | 1.5 |

| Manchester Metrolink | 46 | 4.1 |

| Croydon Tramlink | 38 | 3.9 |

| Sheffield Supertram | 54 | 4.5 |

| City Class | 22 | 1.0 |

The City Class tram has been extensively tested in Birkenhead and Blackpool.

Picture by Alan Robson ©2006

Picture by Alan Robson ©2006

TPL City Class and Centenary trams at Blackpool

Picture by Alan Robson ©2006| Home |

| Introduction |

| Central London |

| NAO Report |

| Costs Too High |

| Reducing Costs |

| Finance |

| Other Ways |

| Conclusion |

| Links |

| Contact Us |

| FAQ |

|

| Copyright © 2012 London Tram. All rights reserved. |

|

Site design by WEBWIZARDS |

||

| This web site is W3C compliant | ||||